Unit D, 16/F, One Capital Place, 18 Luard Road, Wan Chai, Hong Kong.

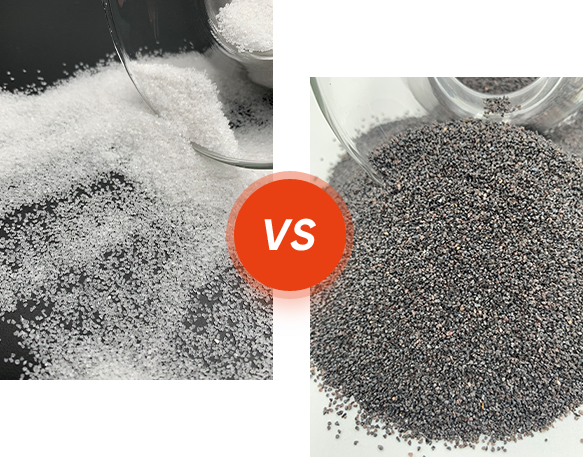

The main raw material of brown fused alumina is bauxite, and the others are anthracite and iron. The material of white v is alumina powder.

Brown fused alumina is made under high temperature by mixing the calcined bauxite, iron and carbon in arc furnace.

As refractory castables, such as steel mills, iron mills, brown corundum as filling smelting furnaces or as coatings for smelting furnaces, the common particle sizes of sand are: 0-1mm, 1-3mm, 3-5mm, 5-8mm, 200mesh, 325mesh and other different segments of sand are selected according to different processes.

As sandblasting and rust removal, such as aluminum products, copper glass, sand washing, the commonly used brown fused alumina sand grain sizes are 16#, 24#, 30#, 36#, 46#.

As abrasives, according to different process requirements, the commonly used grit sizes are 8#, 14#, 20#, 24#, 30#, 36#, 46#, 54#, 60#, 80#, 100#, 120#, 150#, 180#, 220#.

Used for polishing and grinding, such as polishing of mechanical surface, glass surface, and beautification of handicrafts, the commonly used micropowder particle size are 220 mesh, 240 mesh, 325 mesh, 500 mesh, 800 mesh.

As the wear-resistant floor, such as school playgrounds, parking lots, park squares and other grounds that need anti-skid and wear-resistant treatment, you can choose the third-grade brown fused alumina with a lower content of brown fused alumina.

Make the wear-resistant and non-slip pavement. Brown fused alumina is used for laying wear-resistant and anti-skid pavements, bridge decks, and steep slopes of parking lots. It is used as wear-resistant aggregate for plastic floors. It has good wear-resistant and anti-skid properties. Comparing with the original high-grade aggregate laying, it has a very high cost-effective advantage.

Used for grinding and polishing materials. The surface polishing process by brown fused alumina grains has lower pressure, which avoids leaving very fine lines on the surface of the steel plate. The polishing workpiece has good consistency, and the workpiece will not be burned, and the processing efficiency is high.

Make resin abrasives. Use 30%-50% of brown fused and black fused alumina to compound to make resin abrasives. Compared with traditional resin abrasives, the resin abrasives made of this composite abrasive have significantly improved sharpness and higher cut or grinded finish, and the color becomes smaller. Due to the low cost, the resin abrasive tool made of composite abrasives has a low cost performance.

Make coated abrasives. The application of brown fused alumina series products in the field of resin abrasives and coated abrasives is to replace some other abrasives, and partially replace other abrasives to make abrasives. High-cost abrasives are equivalent, but they will reduce the production cost of abrasives and greatly improve the cost performance.

Other applications. Brown fused alumina abrasive with fine particle size is used as an additive for wear-resistant and fire-resistant coatings; sandblasting for old jeans; wear-resistant and anti-skid materials added to the outer side of the heel and heel in the shoe industry; making unshaped refractory materials; making fire insulation materials under medium and low temperature.